Suspended oil online monitoring (WQMS)

The benefits of accurate suspended oil (oil in water) online monitoring are countless with regards to process and wastewater management, especially in the oil and gas industry. Continuous hydrocarbons monitoring enables complete environmental compliance, detailed process optimisation and reduced operating costs often by the use of a single instrument.

- Improves systems nominal capacity

- Ensures safe purge and filtration operations

- Eliminates manual handling and intermittent attendances

- Decreases oil losses and hydrocarbons released

- Prevents bacterial contamination and equipment corrosion

- ATEX and application specific engineered versions available

- Maintenance Free, purge time counter and auto-stop function

- Automated fully programmable system

- Suitable for all type of Hydrocarbons

- Intuitive interface through touch screen

Discharge management

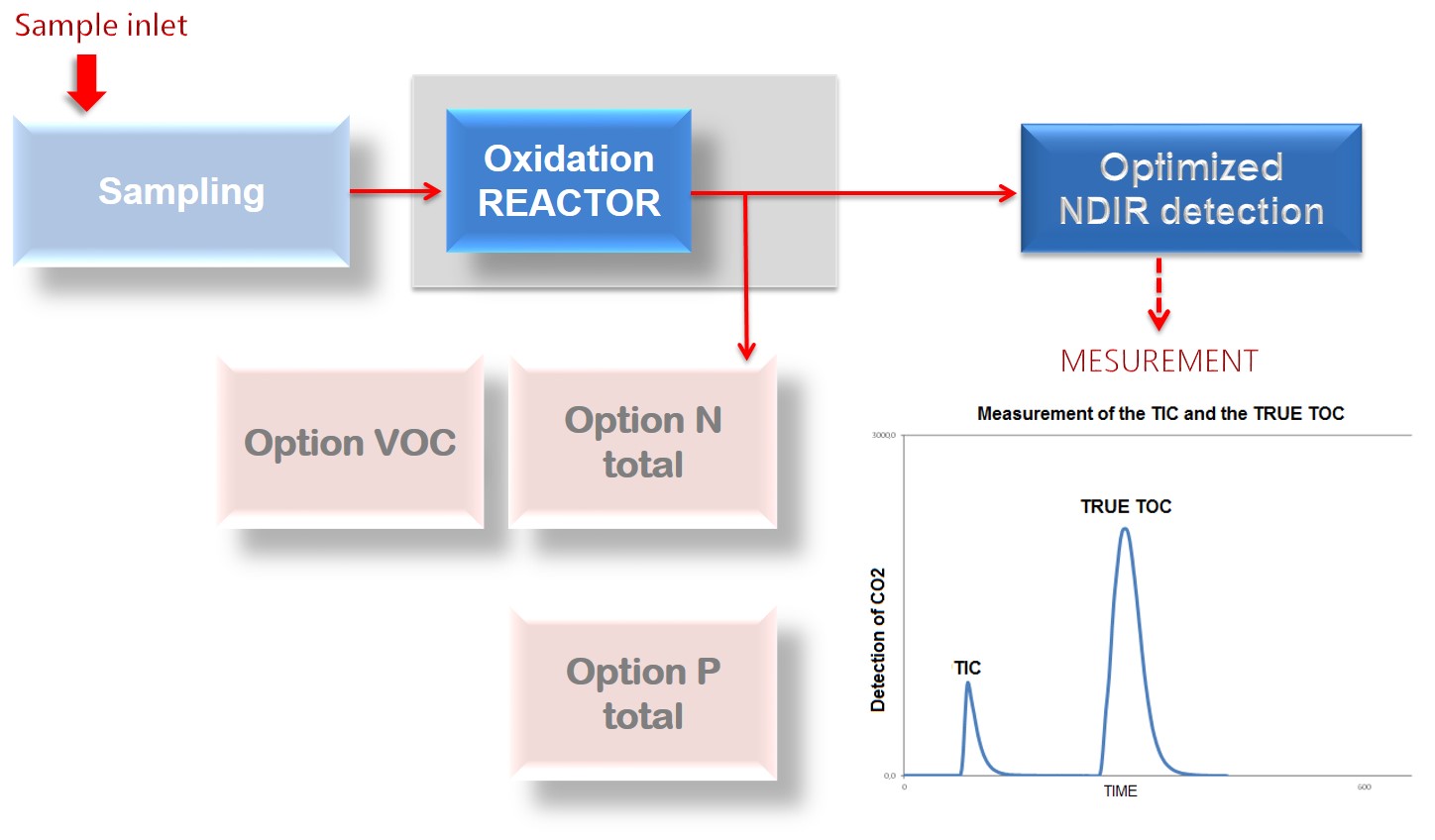

Oil platforms, refineries and Tank farms generate produced water which requires close management. For every country in Oceania, there are regulations setting limits on the amount of hydrocarbons than can be disposed of overboard and a range of different lab techniques that can be used for reporting this amount. The OPAL and PAUTBAC II from SERES IR based analysers can provide continuous measurement of the oil concentrations in the discharge water from oil and gas processing and storage facilities.

Process optimisation

The OPAL and PAUTBAC II from SERES are respectively side stream analyser and oil tank de-watering systems based on IR light scattering. They not only can provide you with extremely accurate monitoring, but also sense for changes in the size of oil droplets and therefore in process conditions. Using the built in IR detector, the OPAL and PAUTBAC II analysers enable early detection of oil traces in all type of water, ensuring fast overview of the process conditions.

As the volume of your discharge water increases, you need a system that will meet your changing demands, work reliably and with minimal operator input required. Having provided hundreds of online monitoring systems worldwide, SERES is the best positioned to assist you along with your water management plan.

Oil Pollution Alarm

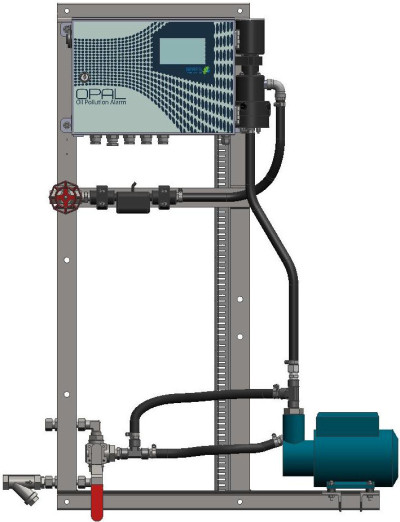

Every platform, refineries, industrial process (…) has to recover as much oil as possible, as efficiently as possible. In order to make improvements you need to understand how the current system is working. SERES Environnement manufactures the OPAL (IMO* certified) allowing real-time measurement of oil concentrations at the inlet and outlet of any separator, providing continuous on-line information about the effectiveness of your separators. The OPAL can also trigger a divert valve to route the produced water through a sand filter.

The OPAL is the last generation of detector designed for online and Real-time suspended Hydrocarbons monitoring. It uses Infra-Red scattering to enables early detection of oil in any type of water. Reagent’s free, the OPAL represents the most cost effective solution and matches a large range of application requirements.

* IMO International Maritime Organisation

PAUTBAC II

The PAUTBAC II is the best suited system to automate water drainage from oil storage tank. With its capacitive probe, it is a flexible, economical and reliable system capable to handle the crucial but time consuming task of oil tank dewatering without the need for human attendance. PAUTBAC II is designed to be install online and is a fully automatic system with adjustable threshold form 5 to 25% and no tank modifications required

A Teflon coated capacitive probe is inserted in an explosion proof circulation chamber mounted in the tank draining pipe work. The probe measures the dielectric constant to detect the interface between oil and water. The control unit processes the probe signal to control the tank purge valve operation.

key facts about automatic dewatering systems

- Avoid product losses

- Reducing amount of hydrocarbons discharged on waste water / cost for waste water treatment

- Increase tanks capacity

- Prevents tank corrosion

- Eliminates labour costs dues to manual operation

- Reduce risk of personal exposures to chemicals

PAUTBAC advantages

- Completely automatic dewatering process

- No maintenance needed

- No calibration needed

- Elimination of tank penetration

- Easy installation without having to drain tank

- Highly sensitive and reliable

AT THE HEART OF INNOVATION

SERES environnement is continually implicated in the process of technological innovation. « We constantly re-invest in research and development in order to provide our clients with the most advanced technologies. For SERES, the notion of change is a permanent challenge. We work in partnership and collaboration with French and foreign research centres (such as the CNRS – the French National Centre for Scientific Research), Engineering Colleges and Universities. » SERES environnement makes 60% of its turnover on the export market in more than 35 countries with references in the Oil & Gas, Water treatment, Cement and Glass industry, Energy and large manufacturing companies…