Applications and References

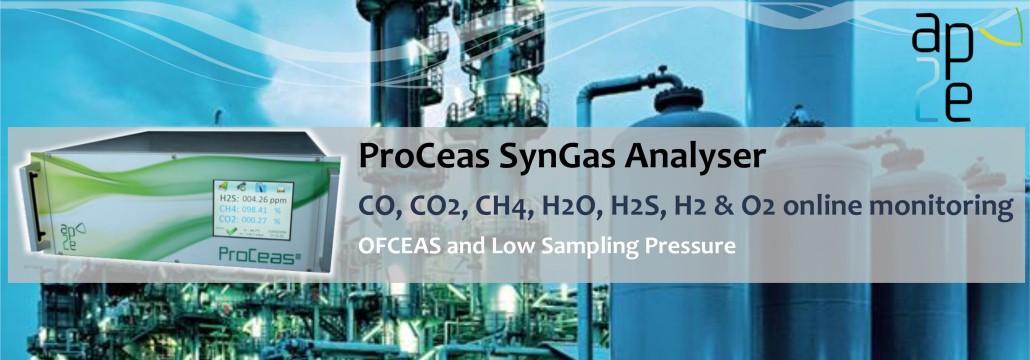

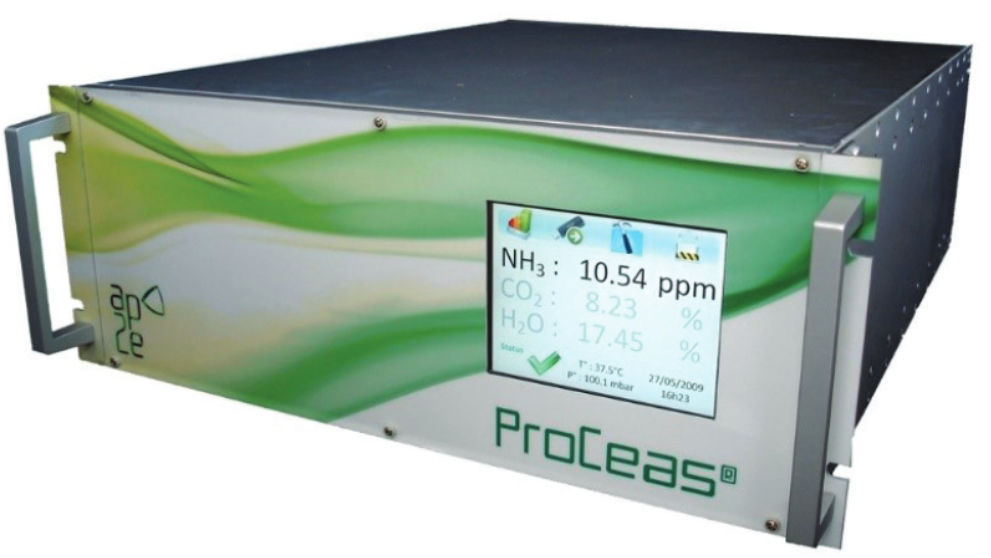

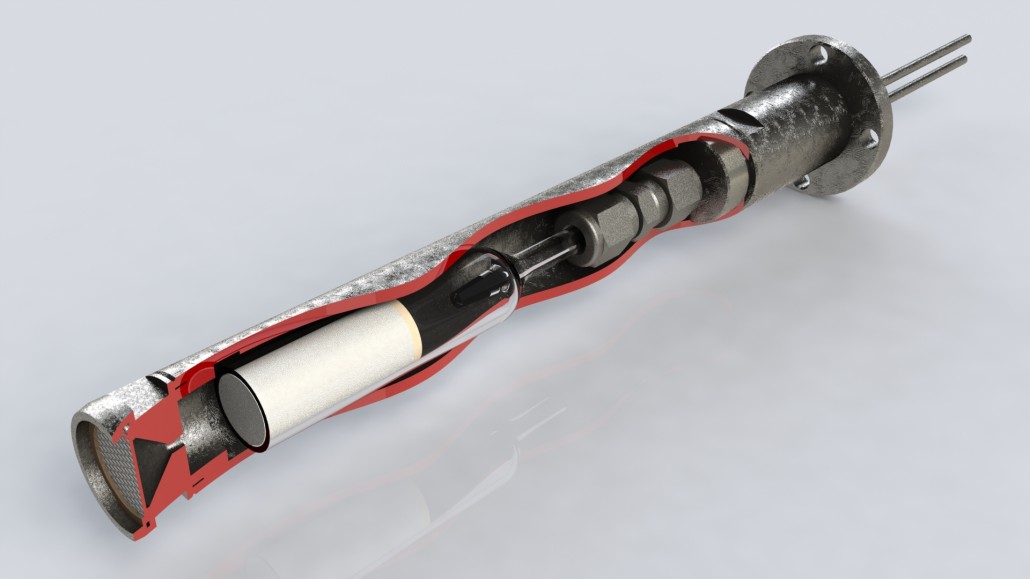

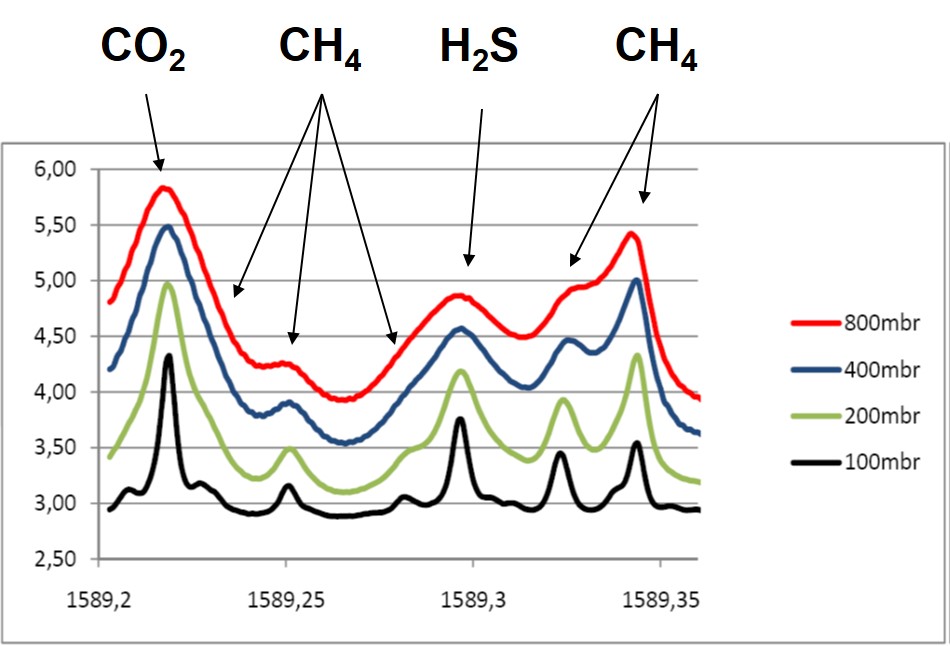

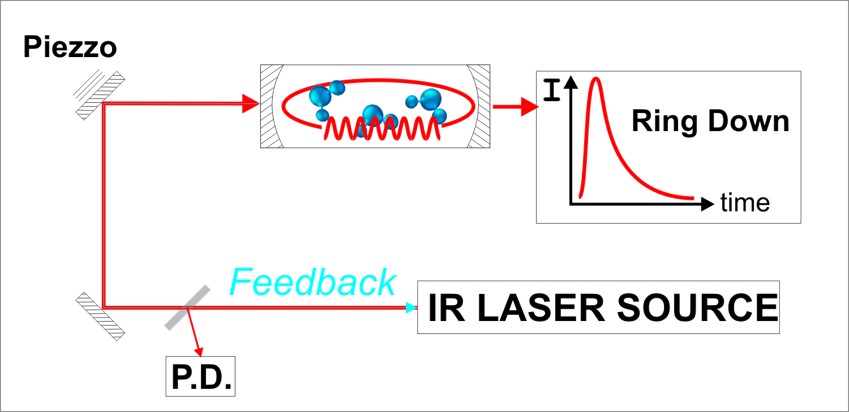

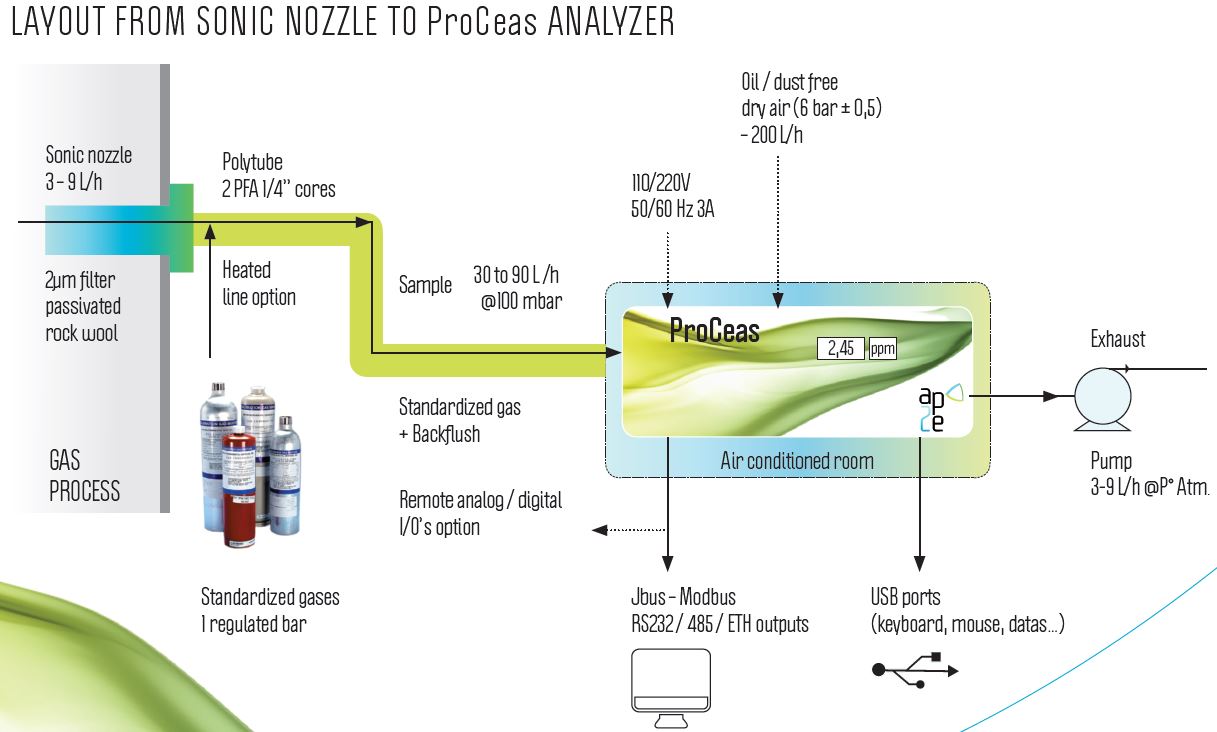

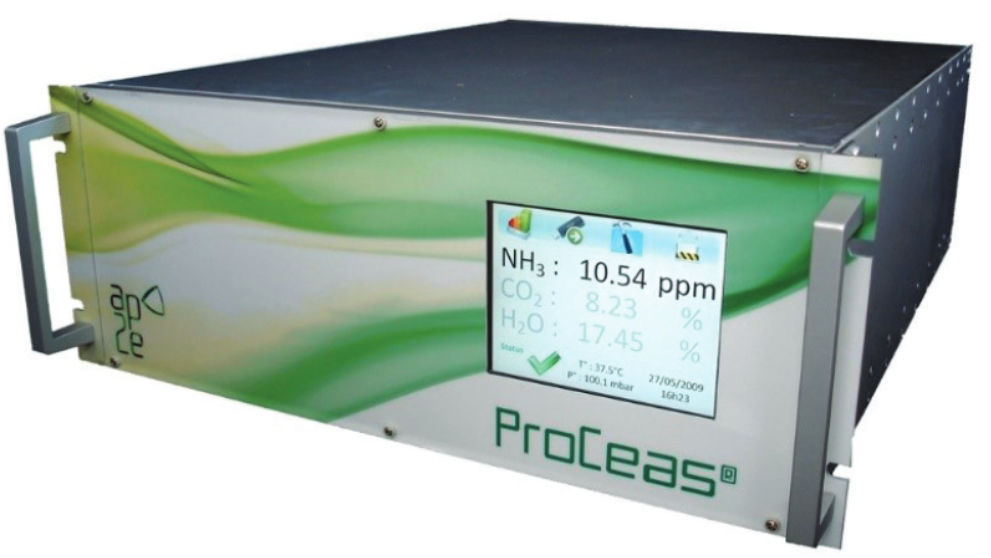

The ProCeas® and the LaserCEM® are based on the OFCEAS* measuring principle combined with a Low Pressure Sampling LPS (100 mbar absolute) developed and patented worldwide by AP2E (France), for the online analysis of several key gases in industrial, environmental and OH&S applications. It provides measurements with a very high spectral resolution in addition to an exclusive and powerful sampling method (no heated line nor treatment of samples) and an interference-free, fast and sensitive analysis, regardless of the matrix of the gas to be analysed.

Combustion cycle in refineries

References: EXXON (optimising combustion in boilers), Fives PILLARD (optimisation tool for the production and the adjustment of burners for boilers).

With the environmental constraints, Oil companies are looking for optimum energy and environmental efficiency of their burners. Combined cycles boilers optimisation requires accurate simultaneous online monitoring of O2 and CO to ensure both compliance with standards and process control efficiency. The ProCeas, used to track real time the residual rate of O2 (less than 3%), ensures optimal combustion process automation. The accuracy of the measurement is a financial matter: according to the thermal performance of the burner, even a reduction of 0.1% of oxygen in excess represents millions of dollars of savings in the annual consumption of fuel.

CEMS in coal fired power station

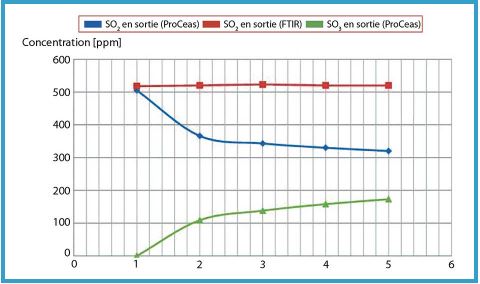

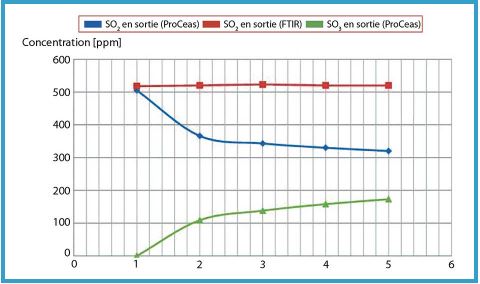

Reference: IBIDEN Power Station – Simultaneous SO2/SO3 monitoring at the catalyst outlet according to the oxygen content variation have been done with the ProCeas® analyser.

SO2/SO3: AP2E also intends to enhance the approach aimed at combining environmental compliance and process optimisation, even if this seems less obvious to understand at first sight. If today SO2 is correctly measured, this does not fully reflect the sulphur emissions from combustion units subject to this requirement. In the presence of oxygen, SO2 does in effect form sulphur trioxide (SO3), a gas that is much more corrosive than SO2.

Other chemical phenomena occur, particularly in denitrification (DeNOx), which in the presence of ammonia may lead both to an over-consumption of ammonia and to filter blockages. Therefore, not measuring SO3 entails the under estimation of sulphur emissions, and also additional maintenance costs and over-consumption of reagents. To have continuous and precise knowledge of the SO2 / SO3 couple enables the operator to choose the controlling conditions for limiting the formation of SO3 and its indirect costs.

References: SP Technical Research Institute of Sweden, Rhodia (France). VEOLIA for its Centre de Recherche Energie Environnement Déchet (CREED, Centre for research on energy, environment, and waste).

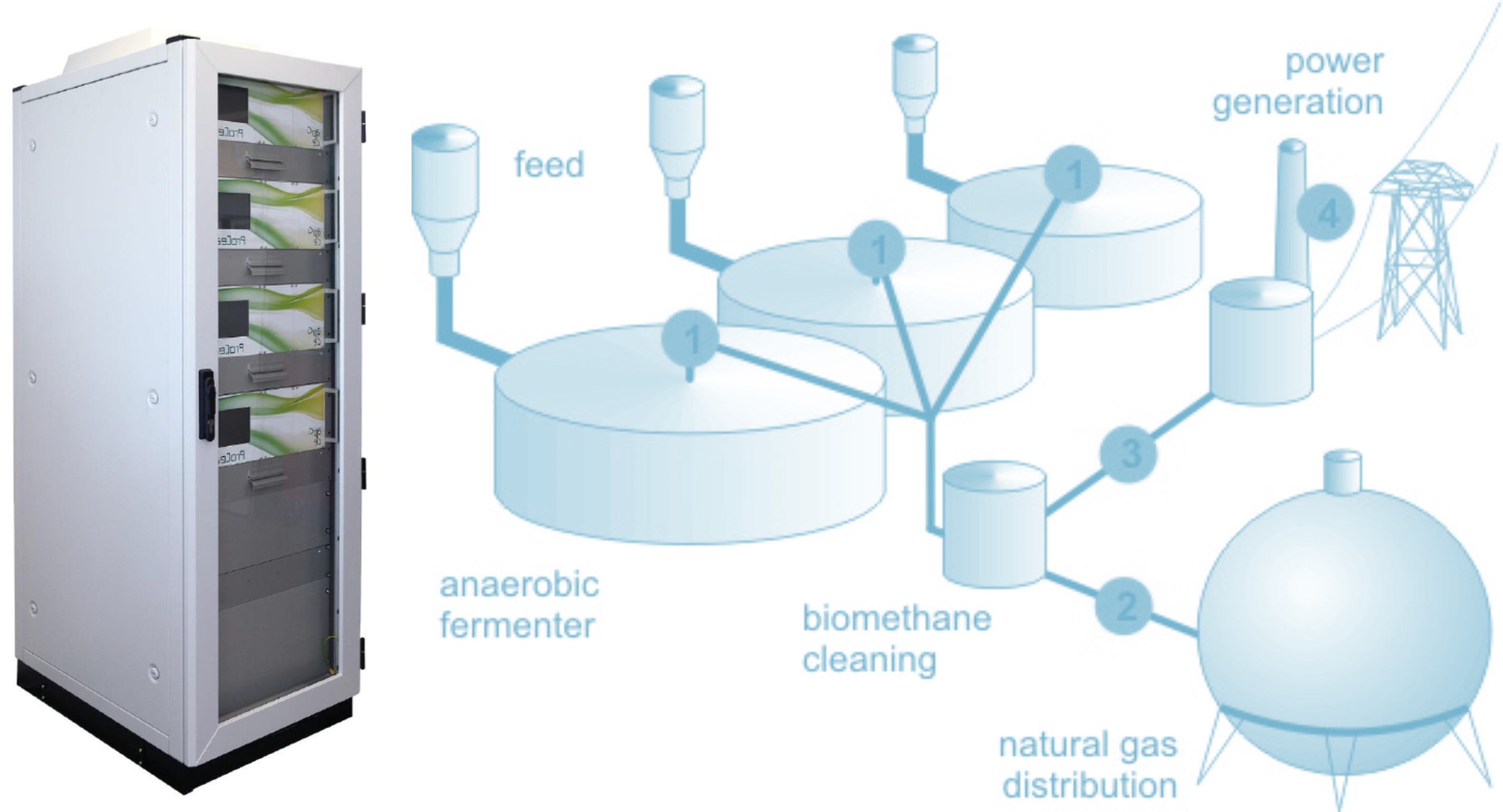

The processing of gases from biomass (biogas, bio-methane) remains a key step in industrial processes for producing various types of bio-energy, a manufacturing process that requires optimizing.

It is therefore imperative to have the ability to calculate the calorific value of these new gases and to be able to quantify the impurities present there, in order to reduce the risk of damage to facilities, to react quickly in case of malfunction, and to certify the quality of finished products. AP2E has installed several equipment units within the facilities of various players of the world of biogas around the world. The purpose is to analyse the CH4 and CO2 content, as well as the residual concentration of H2S. This is a major impurity which transforms into sulphuric acid in the presence of some moisture. It is a very corrosive acid; consequently it is destructive for the facilities and the engines that burn biogas or bio methane.

The ability to analyse in the same multiplexing equipment the H2S content (which varies according to the time of day) of the « raw biogas » at the exit of the casing serves to determine the use of this biogas and assess its composition and quality. Other compounds may also be monitored by adding specific laser sources, such as the water content, in order to control the efficiency of the condenser. AP2E is also currently studying the analysis of siloxane, another sore point for energy recovery.

Using a continuous analyser as a means of industrial control and economic optimization of production units is for the control of biogas quality. During the combined cycles of biogas generation, the absence of H2S is crucial. It is a major impurity and a source of engine breakage. However, conventional means of analysis have trouble distinguishing CH4 from H2S. Therefore, operators are forced to adopt an excessively prudent approach in the treatment stage with active carbon: it is changed even before it is totally saturated. With a continuous, accurate, and reliable analysis of the level of H2S in the exit of the adsorption bed, we can instead use it until its saturation point and reduce overall costs.

Tests conducted on a site with a valuation of 1 MW showed that the amortization of the analyser could be performed based on this single criterion of active coal consumption in less than a year. Indeed the cost of a monthly activated carbon charge is equivalent to AUD $65,000.

References: In 2010, AP2E won an important contract with the DCNS for air quality control equipment for the confined interiors of submarines (on-board crew safety).

In April 2015, European regulations included formaldehyde as a proven carcinogenic product (CMR). In 2014, the ProCeas was certified approved method by EXERA (measurement, control, and automation equipment) and the LNE (National laboratory of metrology and testing).

AP2E is already working in the confined air field (submarines) and is interested in the building sector. This new classification impacts devices monitoring the exposure to workers or to the public of formaldehyde, Freon, Ethanol… present in the indoor air of industrial sites or sites hosting the public. The ProCeas® Formaldehyde continuously measures these changes with a minimum 10 ppm threshold (maximum 1%).

The drying field is another good example of application where energy efficiency has to be kept in mind, especially when processing food powders. Water monitoring is useful for avoiding excessive energy consumption (adjust dryer load to obtain minimise the residual H2O content). Online monitoring of carbon monoxide (CO) answers safety concerns. When food powders are dehydrated, the conditions may be such that CO is generated in the dehydrator. Once conditions for generating CO are present, CO tends to increase its concentration very quickly. To keep the CO below potentially dangerous level, it is necessary to detect the first signs of CO which appear above the levels already present in the atmosphere. The ProCeas is actually in operation within ten drying towers in dry food production facilities and has been chosen as the most reliable monitoring equipment by companies leading food processing industry.

The automobile engines sector also remains a major target. With the arrival of the new EURO VI standards since September 2014, manufacturers have been forced to measure many pollutants (NO, NO2, N2O, NH3, CO2, CH4, and ethanol).

Successful testing with ProCeas® was conducted around the world:

– NH3 at Renault and VOLVO (France)

– N2O at Volkswagen (Germany)

– NH3 at General Motors (USA)

– NH3, N2O, NO, NO2 at Sensor Inc. (USA)

In the USA with Sensors Inc. – (www.sensors-inc.com): in May 2012, AP2E signed a contract for supplying ProCeas® analysers for the real-time control of gas emissions of engine test benches in the automotive industry. Sensors Inc. is the leading American manufacturer of real-time testing equipment for gas emissions in the transportation industry. The new range of measuring instruments is marketed in the US under the name of SEMTECH LASAR and it consists of four modules (NH3, N2O, NO, and NO2), each capable of analysing three gases simultaneously.

To be used in the best conditions, so that it limits damage and maintenance of equipment, natural gas must be rid of impurities, especially hydrogen sulphide (H2S), which is very corrosive, and all traces of moisture. Current filtration systems run against, among other things, the problem of measuring residual traces of these impurities because no reliable continuous analysis system was available so far. Today the main players in the « Oil & Gas » market deem the ProCeas® as the most efficient natural gas analyser for continuously and simultaneously measuring traces of H2S (LoD under 50 ppb) and H2O (under 50 ppm), without interference, without any dependence vis-à-vis the constitution of the gas, and with response times under a few seconds

The ProCeas® is used by pure gases manufacturers to control the purity of the gas along production line (N2, H2, O2…).

References: Total, CEA Grenoble, IFP (French Petroleum Institute), GDF Suez, VEOLIA (CREED), Arkema

H2O, CO, CO2, and H2 rates

Praxair uses the ProCeas® as an online analyser of H2O, CO, CO2, and H2 rates, in a process for producing syngas from the gasification of coal, oil residue, pet coke, and biomass. This syngas is then used either as a source of energy in a heat and electricity combined cycle process or in a Fischer Tropsch process for producing second-generation bio-fuel. This process requires that the residual H2S generated by gasification have a value of less than 1 ppm to avoid the destruction of the polymerization catalysts.

CO, CO2, H2O, CH4, H2S, NH3 and H2

Midrex is a steel manufacturer that uses a gasification process similar to Praxair’s in order to cogenerate the electricity and heat needed in the manufacture of its steel. AP2E delivered to Midrex complete solutions that have enabled it on the one hand to measure the calorific value of these synthetic gases (by measuring CO, CO2, H2O, CH4, and H2) and also the presence of impurities such as H2S and NH3.

H2, H2O and Cl2

Today, the ProCeas® provides what no other infra-red laser technique could: the direct measurement of hydrogen (H2) and water (H2O) in chlorine (Cl2) without reagents or discharges, and interference-free. The ProCeas® performs measurements with a very high spectral resolution of very low concentrations (under a few ppm), with response times under a few seconds. This analyser also provides a control of the drying (H2O) in a chemical process at Arkema.

*Optical Feedback Cavity Enhanced Absorption Spectroscopy: technology developed and patented by the University Joseph Fourier (France), coupled to a Low Pressure Sampling(100 mbar absolute) developed and patented worldwide by AP2E, for the on-line analysis of different gases. By the end of 2010, after two years of R & D studies, the AP2E ProCeas®was the award recipient of the USA “R & D 100” which rewards the 100 most innovative global technologies of the year.

AquaGas is supporting the global industrial community with high performance environmental and process monitoring systems (Continuous Emissions Monitoring Systems, Air Quality Monitoring Systems, Online process analysers, Water Quality Monitoring Systems) specifically designed and built to meet your application requirements.